BGA Assembly

BGA Assembly Services

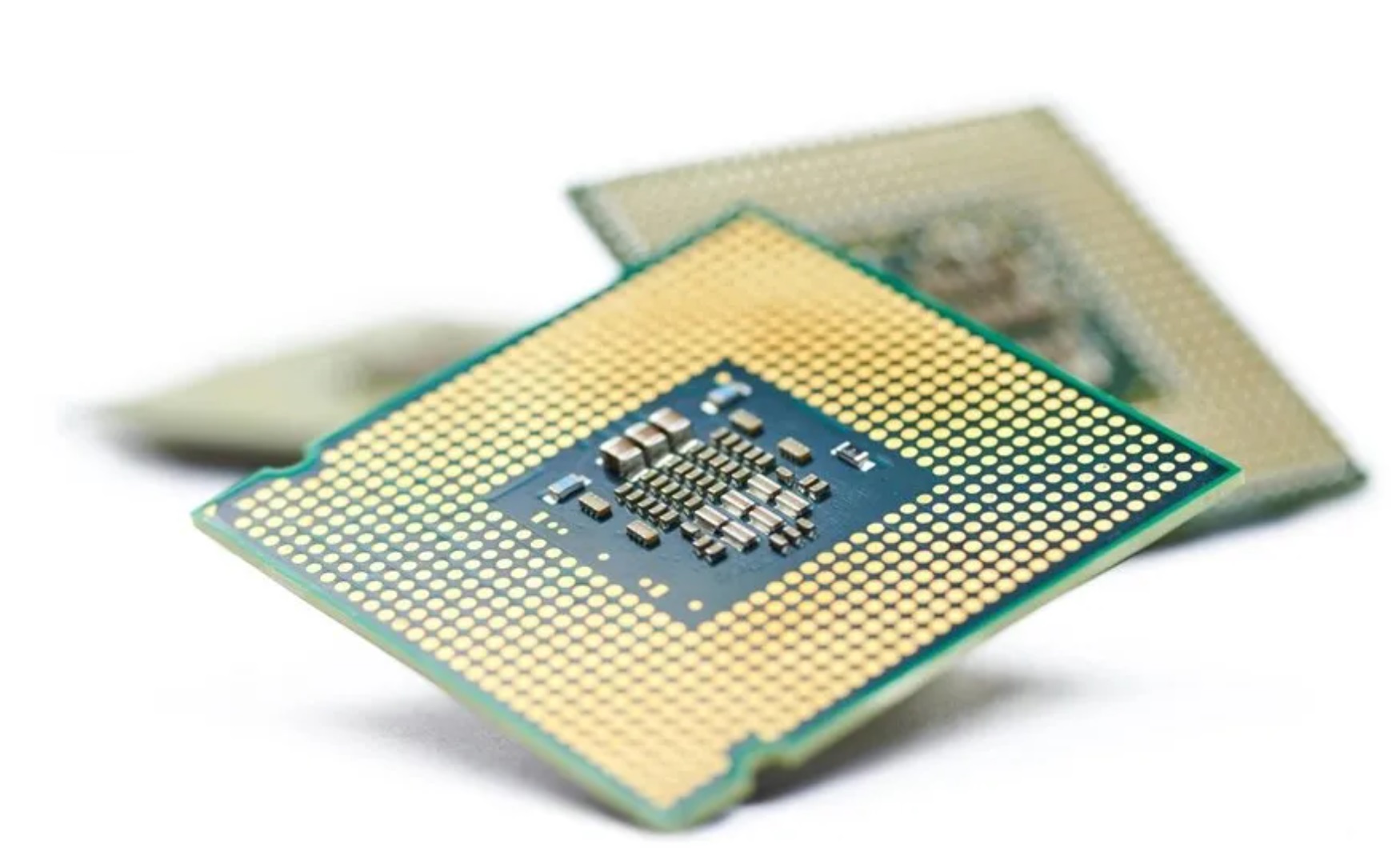

BGA assembly (Ball Grid Array Assembly) plays a crucial role in chip design PCBs to place BGA (ball grid array) parts. BGA assembly was used in complex PCBs. It uses a fine-pitch assembly method to place BGA parts on the parts. BGA offers low assembly costs and excellent density to the customer.

What are the advantages of a BGA assembly?

1. Improves both electrical and thermal performance while making efficient use of space.

2. Reduces the overall thickness of the board.

3. Minimizes the chances of PCB damage since BGA leads are made from solid solder balls, consequently reducing maintenance and repair times.

4. Suitable for miniature packages with high pin count.

5. Offers improved solderability, resulting in a speedy assembly procedure.

6. Dissipates heat quickly due to low thermal resistance.

PCBBOX offers with high quality BGA assembly services to global customers. Our BGA assembly soldering can be ensured in process controls of solder paste printing, reflow oven temperature management, SPI and AOI inspections, X-Ray inspection and function test.

How to ensure good soldering in BGA assembly?

1. Adequate heat should be applied so that all the balls in the grid melt to realize a strong bond for every BGA solder joint.

2. The surface tension of the molten balls locks the BGA package in place until the solder cools and solidifies. A temperature-controlled soldering process is essential for establishing quality solder joints. This practice also prevents solder balls from short-circuiting each other.

3. The configuration of the solder alloy and soldering temperature is chosen precisely so that the solder doesn’t completely melt but stays semi-liquid. It allows each ball to stay separate from its neighboring balls. Always stick to the reflow temperature profile given by your component manufacturer.