SPI/AOI/X-Ray

Robust Inspections

SPI/AOI/X-Ray

In the context of Surface Mount Technology (SMT), SPI stands for Solder Paste Inspection. It’s a critical process used to ensure the quality of solder paste printing on printed circuit boards (PCBs).

SPI systems use laser-based scanning technology to measure the thickness, area, volume, and regularity of the solder paste deposits. This helps detect any defects or inconsistencies early in the assembly process, which can prevent issues like poor solder joints and reduce overall production defects.

Advantages of SPI

1. Improved Quality Control: SPI can detect defects in the solder paste printing process, such as insufficient or excessive paste, misalignment, and bridging. Early detection allows for immediate corrections, leading to higher-quality solder joints.

2. Reduced Rework and Scrap: By catching defects early, SPI reduces the need for rework and decreases the amount of scrap material, saving time and costs in the production process.

3. Increased Efficiency: Automated SPI systems provide quick and accurate inspections, improving the overall efficiency of the SMT process. This helps in maintaining a smooth production flow.

4. Process Optimization: SPI data can be analyzed to identify trends and recurring issues, enabling process improvements and optimization. This leads to better control over the solder paste printing process.

5. Yield Improvement: With better control and early defect detection, the overall yield of the SMT production line improves, resulting in more functional and reliable electronic assemblies.

6. Traceability: SPI systems often come with data logging capabilities, allowing for traceability of defects and process parameters. This is crucial for quality management and continuous improvement efforts.

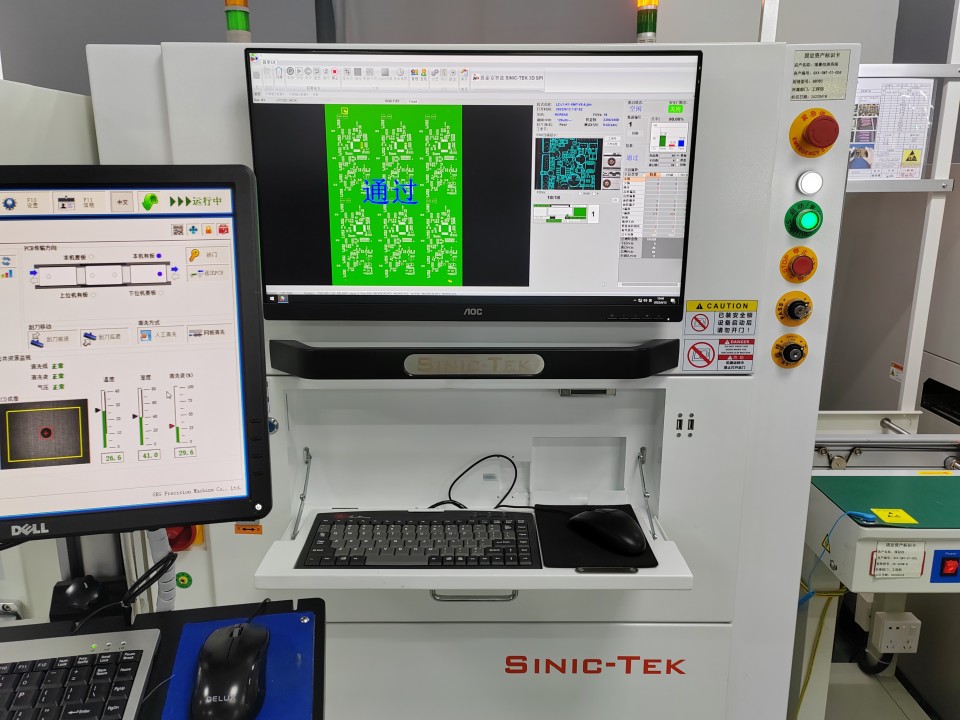

AOI (Automated Optical Inspection)

In Surface Mount Technology (SMT), AOI stands for Automated Optical Inspection. It’s a powerful inspection method used to ensure the quality and accuracy of PCB (Printed Circuit Board) assemblies. AOI is typically used at various stages of the manufacturing process, including post-reflow inspection, to ensure that the final product meets quality standards.

High-Resolution Imaging

AOI systems use high-resolution cameras to capture detailed images of the PCB assembly.Image Comparison

These images are compared against a "golden board" reference to detect any discrepancies.Defect Detection

AOI can identify a wide range of defects, such as missing components, misaligned parts, soldering issues (like bridges or insufficient solder), and other quality defects.

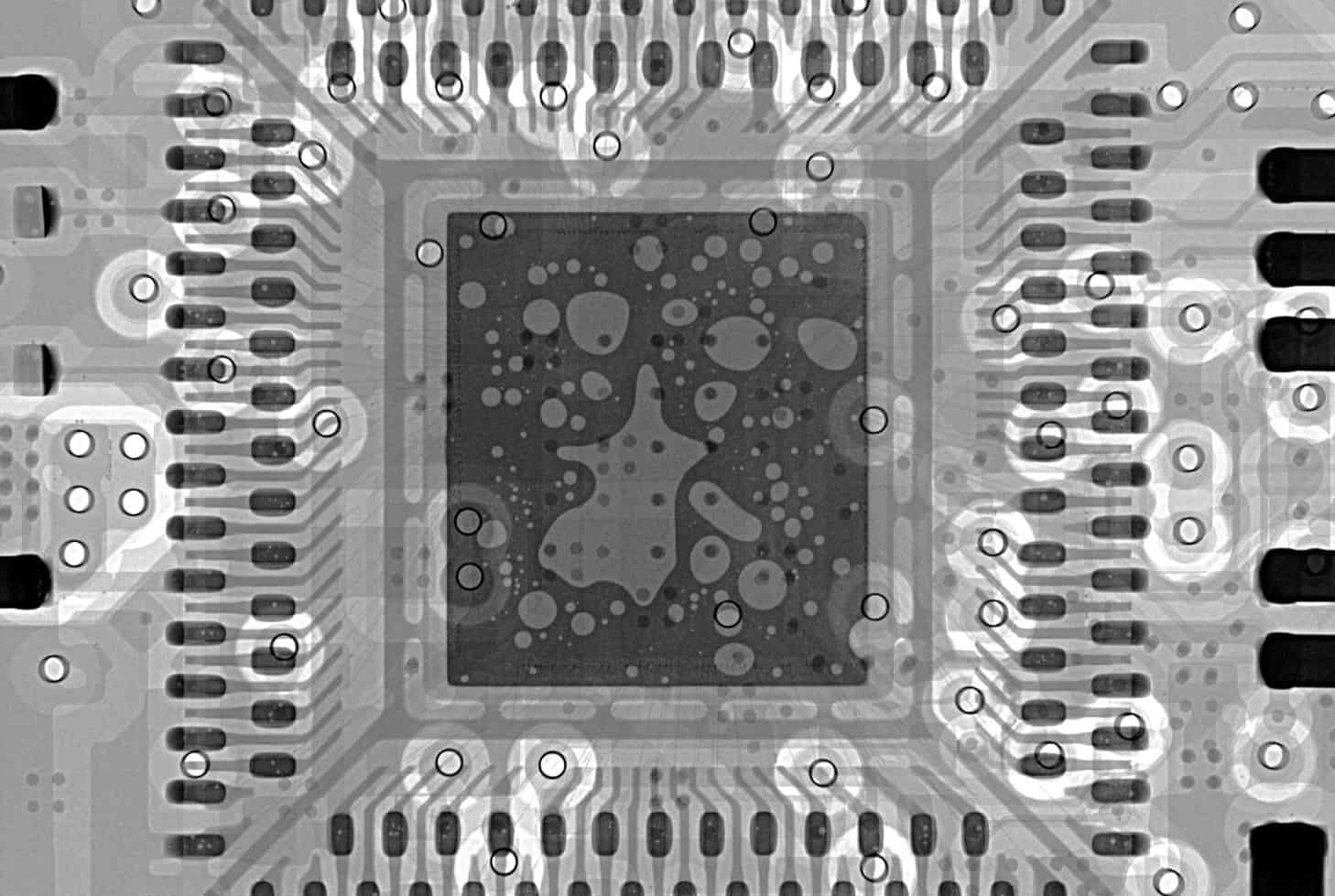

X-Ray Inspection

In Surface Mount Technology (SMT), X-ray inspection is a powerful non-destructive testing method used to examine the internal features of PCBs (Printed Circuit Boards) and their components. Here’s how it works and why it’s important.

How X-ray Inspection Works:

1. X-ray Source: An X-ray source generates X-rays that penetrate the PCB.

2. Detection: The X-rays interact with the materials inside the PCB, creating a pattern of shadows based on material density and thickness.

3. Image Capture: A detector captures these X-ray images, which are then processed to create detailed 2D or 3D images of the internal structure.

4. Defect Identification: These images are analyzed to identify hidden defects such as voids, solder bridges, open joints, and misaligned components.

Advantages of X-ray Inspection in SMT

1. Hidden Defect Detection: X-ray inspection can reveal defects that are not visible through external visual inspection, such as issues within multilayer boards or concealed solder joints.

2. Improved Quality Control: By detecting internal defects early, manufacturers can ensure higher quality and reliability of electronic assemblies.

3. Non-Destructive: Since it doesn’t damage the PCB, X-ray inspection is a safe method for quality control.

4. Efficiency: Automated X-ray inspection systems can inspect multiple PCBs quickly, increasing production throughput.

5. Cost Savings: Early detection of defects reduces the need for rework and minimizes the risk of product reworks.