PCB Design

PCB Design Services

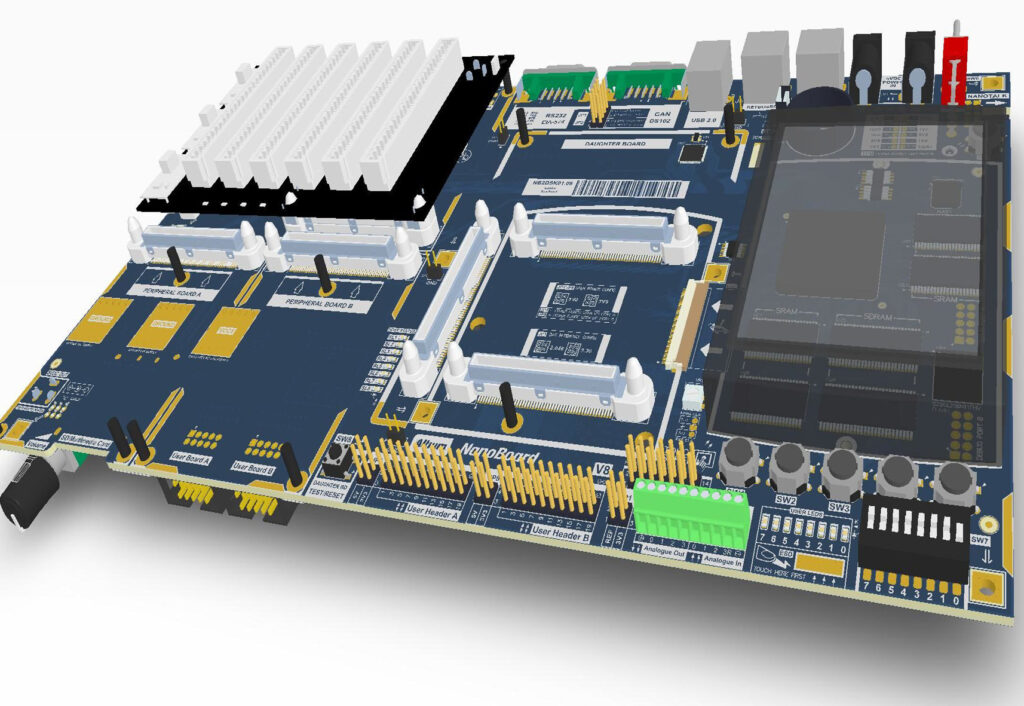

PCBBOX team design printed circuit boards of any complexity: rigid, flexible, multilayer, HDI boards, high-speed PCBs, and other types and can create boards from scratch or improve an existing electric circuit design. We will create a prototype, develop embedded software, test the product, and prepare PCB design and layout documentation.

PCBBOX creates analog, digital, and mixed-signal boards for custom electronics. As a PCB design company, we can provide consultation, evaluate your project, and offer a full cycle of development – from schematics and layout to testing and validation. We use the DFMA approach in our work and can help you with certification and production launch.

Our turnaround time varies on the complexity of your designs, for simple 2-4 layers we take 4-5 days, and for more complex designs our team takes up to 8-10 days.Rest assured, you don’t have to wait a lot as our designers are ready to start working on your projects immediately, ensuring timely and efficient delivery of your PCB designs.

High Quality Analysis

Cost Efficient

Timeline Management

Deliverables

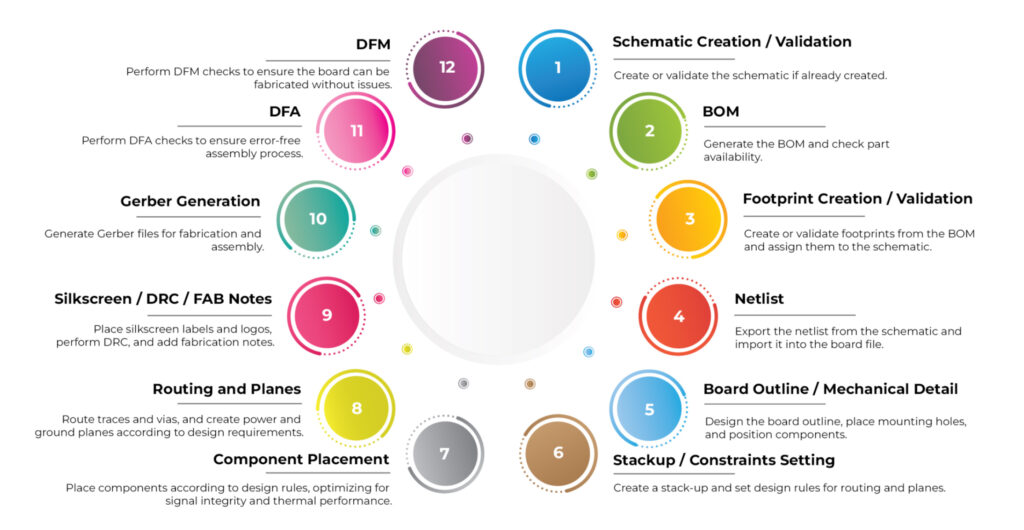

PCBBOX engineering team comply with 12 PCB design approaches to complete your design and hand over following deliverables.

- Complete Schematic drawings

- PCB layer stack drawings.

- Complete 3D PDF files

- Fabrication files (Standard format is Gerber Extended; Gerber X2, ODB++, IPC-2581 available upon request)

- Rout and Drill files

- Assembly drawings

- Pick and Place files (Centroid Data)

- Fabrication specifications (Layer Stacks, Drill Tables and Drawings, etc.)

- Complete Bill of Materials list (BOM)

- Other customer specified outputs