Aluminum PCB

Home / Aluminum PCB

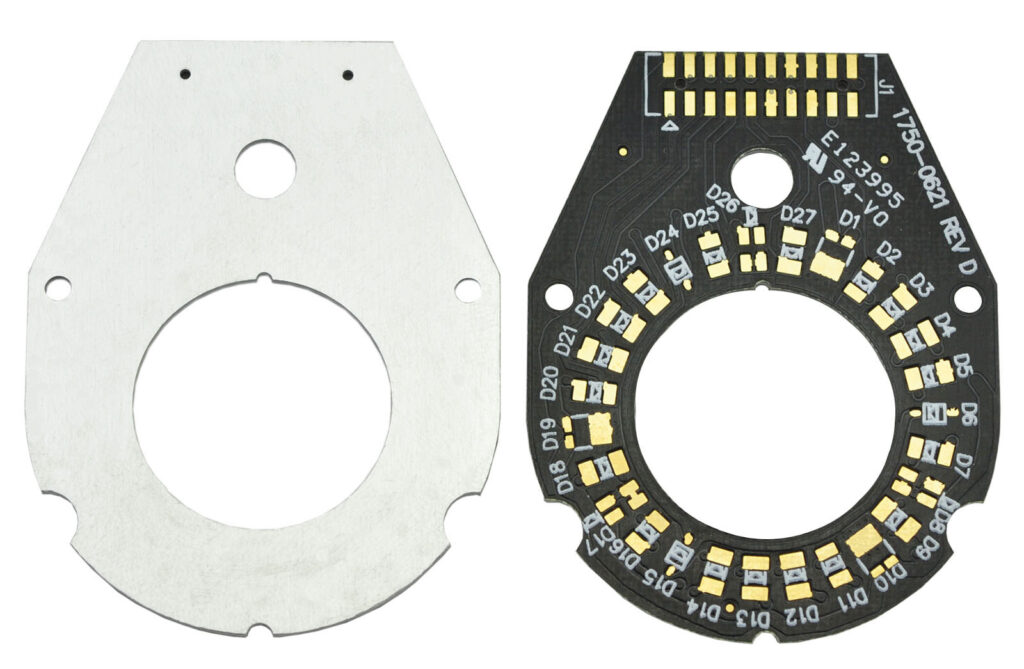

Aluminum PCB Fabrication

PCBBOX is offering aluminum PCBs to global customers with excellent quality and cost efficiency, which are widely applied in lighting projects. Aluminum PCBs are also known as metal-core PCBs, a type of printed circuit board that uses aluminum as the base material instead of the traditional fiberglass, with advantages:

1. Thermal Management: Aluminum PCBs have excellent heat dissipation properties, making them ideal for high-power applications.

2. Durability: The aluminum base provides mechanical stability and resistance to physical stress.

3. Lightweight: Aluminum is lighter than other metal bases, making it suitable for applications where weight is a concern.

| Items | Performance Index (Measured value) |

| Peeling strength (n/mm) | 1.8 |

| Insulation resistance (ω) | >1*10 g |

| Breakdown voltage (vdc) | >2 k |

| Soakable soldering (°C/m) | 280°C / 260°C, 1 min, no bubble & delamination |

| Thermal conductivity (ω/m-k) | >0.8 |

| Thermal resistance (°C/ω) | < 1.2 |

| Combustibility | fv-o |

| Dielectric constant (1mhz) | 4 |

| Dielectric loss angle (tangent) | 0.03 |

| Feature | Capability |

| Quality Grade | Standard IPC 2 |

| Number of Layers | 4 – 24layers |

| Order Quantity | 1pc – 10000+pcs |

| Build Time | 2days – 5weeks |

| Material | Aluminum core (Domestic 1060), Copper core, FR4 covering |

| Board Size | Min 6*6mm | Max 610*610mm |

| Board Thickness | 0.8mm – 5.0mm |

| Copper Weight (Finished) | 0.5oz – 10.0oz |

| Min Tracing/Spacing | 4mil/4mil |

| Solder Mask Sides | As per the file |

| Solder Mask Color | Green, White, Blue, Black, Red, Yellow |

| Silkscreen Sides | As per the file |

| Silkscreen Color | White, Black, Yellow |

| Surface Finish | HASL – Hot Air Solder Leveling Lead Free HASL – RoHS ENIG – Electroless Nickle/Immersion Gold – RoHS |

| Min Annular Ring | 4mil |

| Min Drilling Hole Diameter | 6mil |

| Other Techniques | Countersink holes Screw holes |