Multi-Layers PCB

Multi-Layers PCB Fabrication

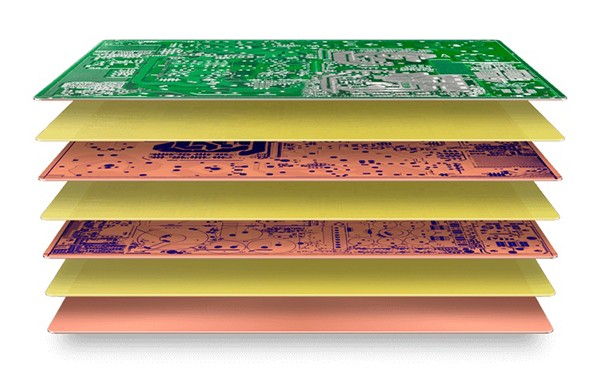

PCBBOX can offer multi-layers PCB with excellent quality and cost efficiency. The number of layers is up to 36, which can meet needs with complex design and for compact devices. Basically, a multilayer PCB has three or more layers of copper foil, insulated from each other by lamination or coating, and joined together to form a single piece. The outer layers are usually single-sided PCBs, while the inner layers are double-sided PCBs.

-

Layers up to 36

-

Quick turn & no MOQ

-

AOI inspection

-

Free 100% electrical test before shipment

With the rapid development of technology, there is a great demand for advanced PCBs. Now the advanced PCB has been widely used in high-end and high-precision electronic devices, such as automotive electronics, complex industrial equipment, complex computing, instrumentation, as well as communication equipment, etc. So multi-layers PCB design is becoming popular. Runrays have robust manufacturing capabilities of deliver 2-36 layers PCB according to customer design files.

| Item | Capability |

|---|---|

| Material | FR4 Tg 140C/150C FR4 High Tg 170C/180C FR4 Halogen-Free FR4 Halogen-Free & High Tg |

| Board Type | Multilayer Rigid PCB Multilayer Flex PCB Rigid-Flex Multilayer PCB |

| Layer Count | 1-32layers |

| Board Dimension | 6mm*6mm – 600mm*700mm |

| Board Thickness | 0.6mm – 3.2mm |

| Copper Weight | 0.5oz – 6oz |

| Min. Spacing/Tracing | 3mil/3mil |

| Surface Finish | HASL (lead & lead-free) ENIG Immersion Silver/Tin OSP |

| Min. Annular Ring | 3mil |

| Aspect Ratio | 10:1 |

| Min. Drilling Hole Diameter | 6mil, 4mil (laser drill) |

| Other Techniques | Blind/Buried Via Gold Fingers Press Fit Via in Pad Electrical Test |