PCB Assembly

Home / PCB Assembly

PCB Assembly Services

Responsive & Cost-Effective

PCB Assembly Services

PCBBOX focuses on one-stop PCB assembly (PCBA) services including components procurement, supply chain management, SMT&DIP soldering, ICT/ICT test, conformal coating etc. to global customers for years.

Quick Turn Prototypes

PCBA prototypes can be completed as less as 7 days if for urgent orders.

Read More 19

Countries where customers are from

Global customers from 19 countries trust PCBBOX for years.

558

Successfully completed designs

PCBBOX joined PCB design and manufacturing in 558+ cases for our global customers.

36

%Faster than ever before

PCBBOX fully think about the lead time and shorten delivery beyond expectations.

22

+Batches for components

In order to ensure components quality, PCBBOX only buy components with batch in 3 years.

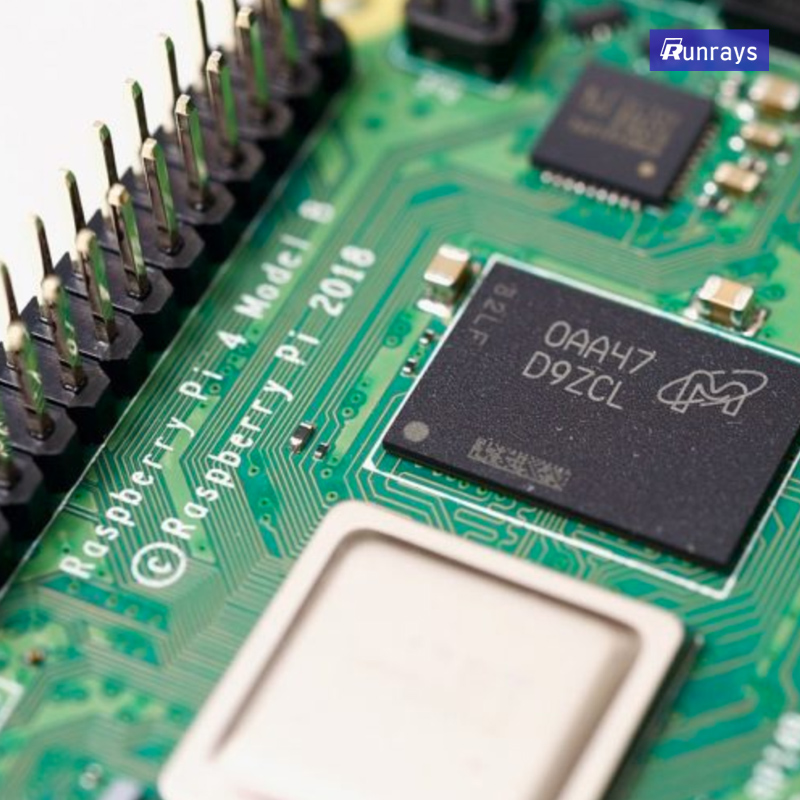

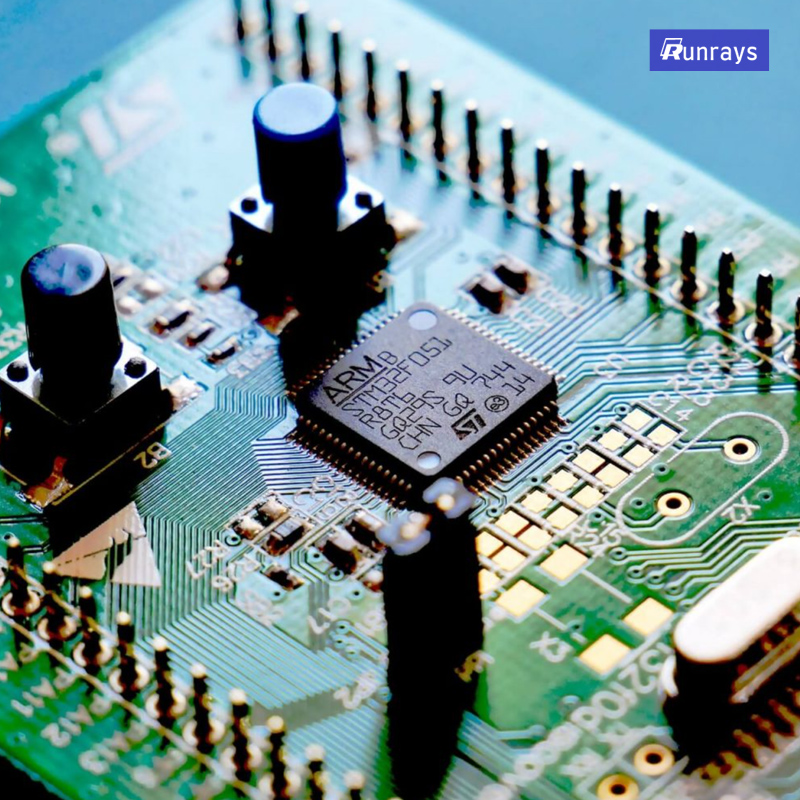

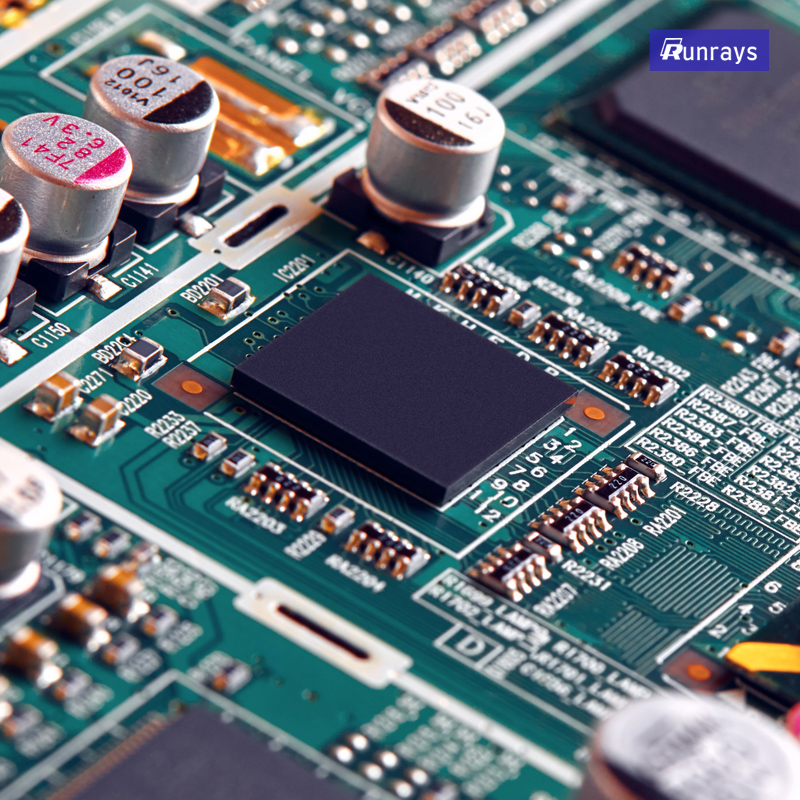

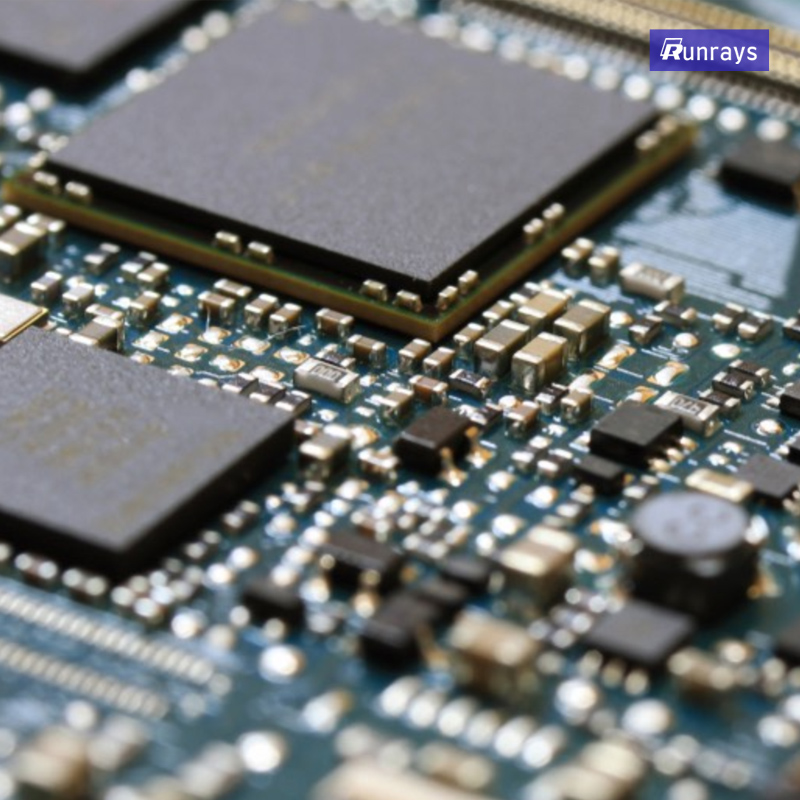

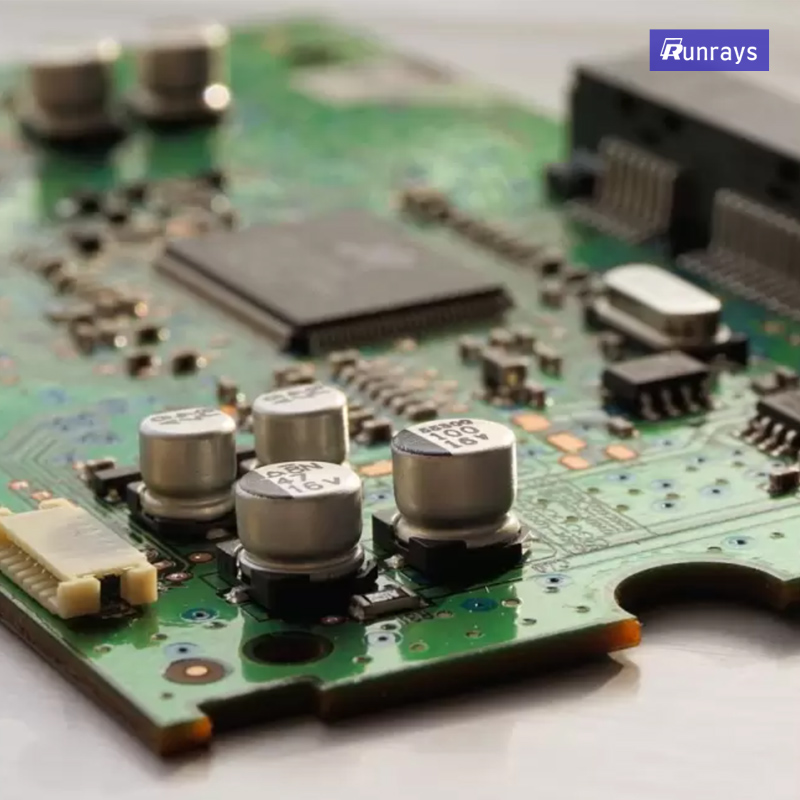

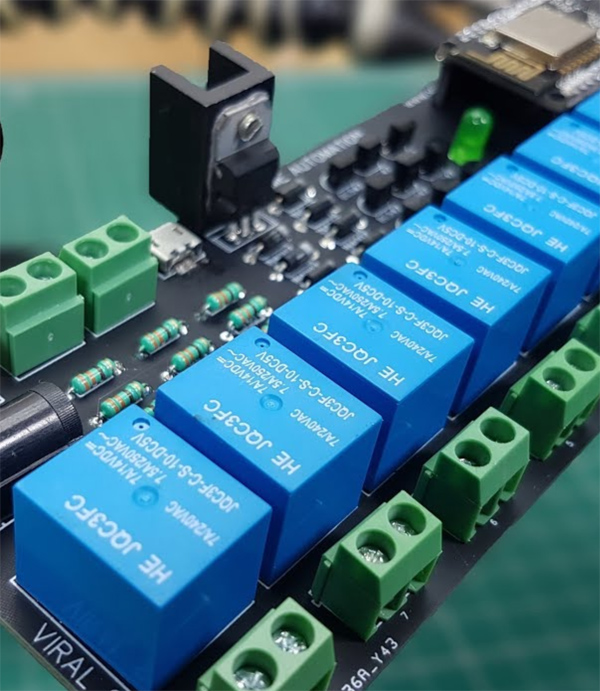

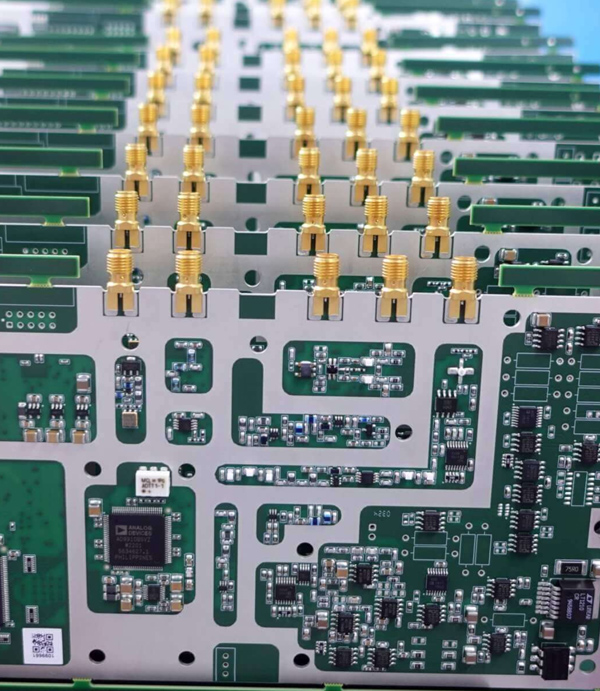

Gallery

PCB Assembly Boards

We have rich experiences of PCB assembly for industries such as medical instruments, system controllers, IoT modules, solar power, communication, consumer electronics, lighting system etc. and have achieved ISO9001:2015, ISO13485, IATF16949, ROHS, CE certificates.

Fetaured service

Make PCBAs

Simple & Efficient.

PCBBOX fully convey key controls & solutions to you and make same things really different.

Our expertise

Completely release pricing list of BOM

PCBBOX will help you to correct possible inappropriate parts and show you cost of every single component in BOM.

Our expertise

Free alternatives cost-down proposal

We can provide you with a professional cost down proposal including component alternatives and engineering process.

ALWAYS THERE FOR YOU

What we do to ensure excellent quality of PCBAs

PCBBOX engineering team have 10+ years experiences in PCB assembly process controls and comply with our quality targets to make you satisfied.

IQC - Incoming Materials Inspection

Control all materials from suppliers and confirm they comply with specifications according to BOM.

100% Function Test (FCT)

All PCBAs will be tested according to customer's test plan by test jigs issued by PCBBOX.

IPQC - In-Process Quality Control

On-site control during production including soldering, first article, visual inspection and related engineerings.

Barcode & Tracking System

If necessary, PCBBOX can control all production process by putting barcode on board and collect data into tracking system.

OQA - Outgoing Quality Assurance

Pick samples from the packed products and ensure they are in good functions and compliance with design.

Safe Packing for Global Logistics

As a standard, all boards will be packed in PE foam and anti-static bags for safe transportation.