DIP Assembly

Home / DIP Assembly

DIP Assembly

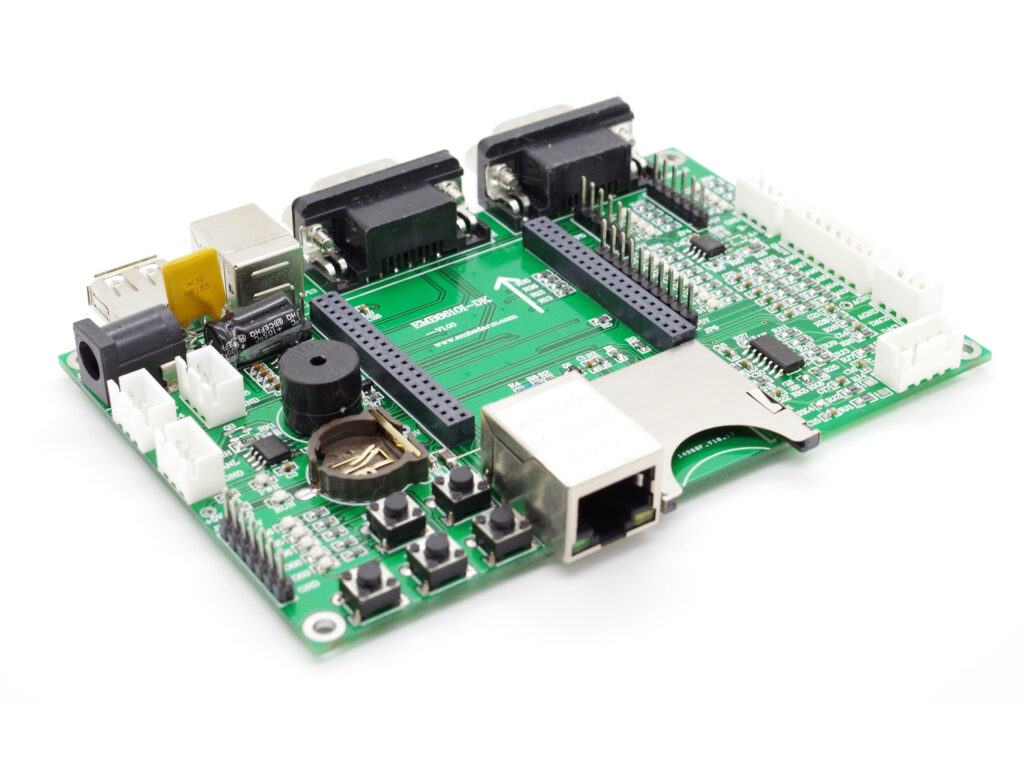

DIP assembly refers to the process of assembling electronic components that are packaged in Dual In-Line Packages (DIP). A DIP is an electronic component package with a rectangular housing and two parallel rows of electrical connecting pins.

-

Through-Hole Technology (THT)

DIP components are typically mounted on printed circuit boards (PCBs) using through-hole technology, where the pins are inserted through holes in the PCB and then soldered on the opposite side -

Standardization

DIP packages are standardized, making them easy to use and replace. This standardization helps in maintaining consistency and reliability in electronic assemblies. -

Ease of Use

DIP components are easy to handle and insert into sockets or PCBs, making them ideal for prototyping and testing.

PCBBOX engineering team have rich experiences of DIP assembly and soldering procedures, including making fixtures, wave soldering temperatures control, loading speed, residues cleaning, pin-cutting and necessary manual soldering etc. Keeping DIP assembly in good quality is huge important for the entire boards.